The

X-Files

The Quest for a Mechanical Rapprochement of Quartz-Accuracy

An inside report of De Bethune SA, La Chaux l'Auberson

by Magnus Bosse, November 2006

Part

2

click on small images to view full-size ones!

2.

Watchmaking at De Bethune today

2.1 Vertical integration bottom-up in the smallest

possible space!

Once you enter the De Bethune building, the impression of traditional

handcrafting in the world of watchmaking will completely vanish:

What you see is computer-controlled machinery everywhere, operated

by technicians. CAD, CNC and spark erosion machines, all magically

selecting and adjusting their tools, fill the rooms on the first floor

(large image and small images, left and middle). Highly sterile and

dust-clean working benches help to foster the feeling of high-tech,

automated production of part. Is this the birthplace of reportedly hand-made watches?

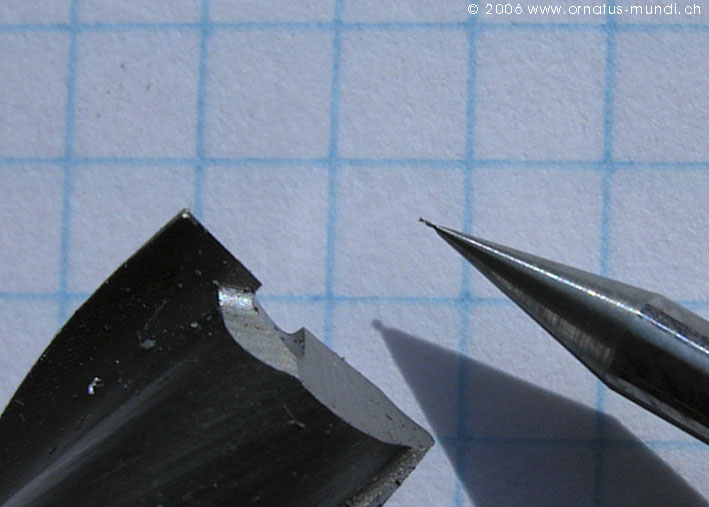

However, there are also traditional lathes still in use, so this should reassure the startled audience. With this equippment, almost all components necessary to build a watch can be produced on a raw state.The precision aimed for with omitting hand-work in the initial production procesess (a strategy now almost universally employed in the watchmaking industry) lies in the range of few 1/1000th of a millimetre. Not surprisingly, the tools used to machine the parts are unbelievably small in scale. Here a CNC moulding cutter is shown (right), side-by-side with a normal drill we all know from the do-it-yourself markets (left):

This machinery

"creates", so to speak, the raw material

for the movements parts, which are then finished by hand by

the master craftsmen - one floor up! But let us take a closer look

at the plates, bridges and levers that come out of the black-box

machinery:

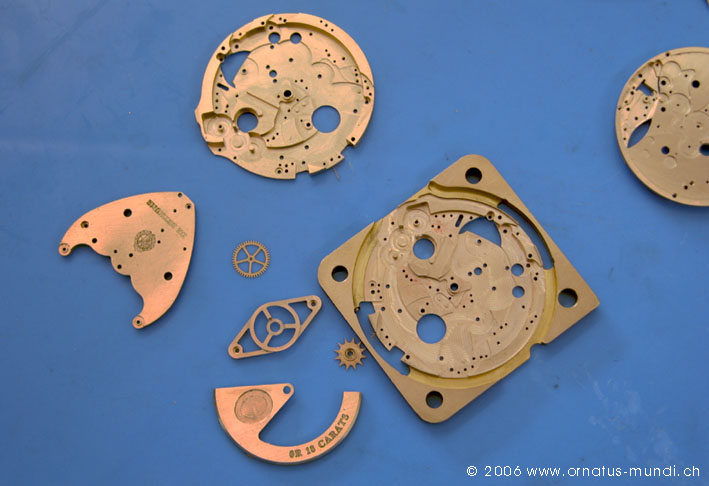

The sophisticated tools allow for a great deal of flexibility, combined

with the necessary precision. Note, that base-plates, cocks, bridges,

but also wheel blanks can be manufactured

(large image). Of note, different materials are use, such as brass

(plates and bridges), red gold (wheels), steel (levers and pinions)

or titanium and platinum (balance components). The

plates are made in a two-step process: Brass blankets are pre-cut

with spark-erosion first to shape the raw plates, and then CNC machines

carve the subtle layers and drill additional whole and structures

not possible with the former

(small images, left: left, plate after spark erosion; left: plate after

CNC treatment). The result is a relatively complex architecture (small

image, middle). As a true manufacture, De Bethune is able to produce

entire gears consisting of wheels mounted on pinions. The combination

of red gold (wheels) and steel (pinions) are a further sign for the

watchmaking class the company is striving for (small image, right).

At this point we leave the first floor, go one staircase up and enter the finishing department. Dedicated craftsmen devote their skills to apply the hand finishing, which by no one else then the noted watchmaker extraordinaire and eccentric Philippe Dufour is called the "soul of Swiss watchmaking". Now lets spend a few minutes to watch the polisher doing his magic:

But this

alone is not responsible for the allure of De Bethune timepieces

- every effort to create ultimate quality would be lost if the dials

and hands would not be made with adequate stringency. Dial and hands

represent the

"face" of every watch, and to me the proverb of "a

watchmaker has to sell the dial, then 50% of the deal is done"

has some undisputable truth.

In La Chaux à l'Auberson, the dials are made of 18kt gold, hand

guilloched (if

applicable; and this is done out-house) and then silvered. The indices

and numerals are printed onto them using a complicated, highly demanding

multiple step printing method, resulting in an almost 3-D look. The

dials of the more complicated pieces consist of several separate elements

and layers, which require maximum precision while being crafted (small

images below, left). But even the simpler dials show the mastery of

the process (small images below, right).

Once the parts are ready, its time to change the room and enter the watchmaker's reign. 20 watchmakers, most of them in their 20s or 30s, are assembling the complicated De Bethune watches using the parts produced under the very same roof. The watchmakers are all "polyvalent", as De Bethune describes it, meaning that they are qualified to execute all necessary steps to build a watch, and depending on the current needs they perform these. Before the parts are handed over to the watchmakers, a quality specialist checks each and every component for specification and finishing (small images below, left). Only with her "placet", it is transferred to a watchmaker's bench and carefully fitted in a De Bethune movement (small images, middle). Finally, the finished watches are checked for timekeeping and function, of course, but also for finishing using a binocular that also is equipped with a timing device (small images, right).

Denis

Flageollet of course from time to time disappears - necessarily, as

he enjoys the creative moments in his "chamber of secrets",

as his own, fully equipped atelier is called. It is located under

the roof of the manufacture, as if the proximity to the sky would

help putting ideas into concepts and finally into working mechanisms.

Lathes, files, drilling tools and timing machines allow the creation

and testing of entire movements in complete isolation.

When I visited De Bethune in 2005, the prototype of the new automatic

calibre laid on the bench, ticking quite

contentedly. Of course, photos were not allowed, but Mr. Flageollet

talked with great pride about the new movement, and considered it

a corner stone of the manufacture's future - a fact that was underlined

with the intense reconstruction work that was underway in La Chaux

(small pic). If he is right in his evaluation - well, make up

your own mind after we tackled the entire collection (chapters 4 &

5)!

Naturally, this is only a part of the story of De Bethune's excellency. The next chapter guides you through the marvellous movements, and opens some X-Files!